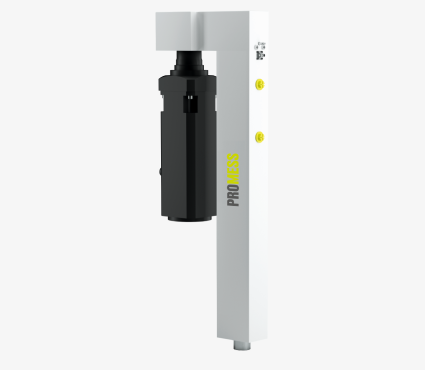

The UFM COMPACT5 Series electro-mechanical assembly units feature a slim, lightweight design perfect for operations requiring multiple presses in tight spaces. Its durable roller gear drive delivers high force in small dimensions, while a synchronous belt ensures precise positioning. The servomotor’s parallel alignment allows for a low installation height, making it ideal for integration into automated lines, manual workstations, or robotic systems. Controlled by PROMESS software, it offers easy programming, real-time force monitoring, and data storage. With 24-bit signal resolution, high accuracy is guaranteed, and the system supports SQL Server and Oracle for seamless quality control and traceability in production processes.

| UFM | Force [kN] | Stroke [mm] | Speed [mm/s] | Article-No. |

|---|---|---|---|---|

| 50 | 350 | 240 | CP5P0500-035-024 | |

| 50 | 350 | 150 | CP5P0500-035-015 | |

| 25 | 350 | 250 | CP5P0250-035-025 |

The assembly of bushings into steering knuckles used in the automotive industry.

The hydraulic press couldn't maintain the required tolerance of +0.5 mm. The customer had limited assembly space for this application.

PROMESS compensated for part variations and fit within the limited space, consistently achieving better than +0.1 mm tolerance.