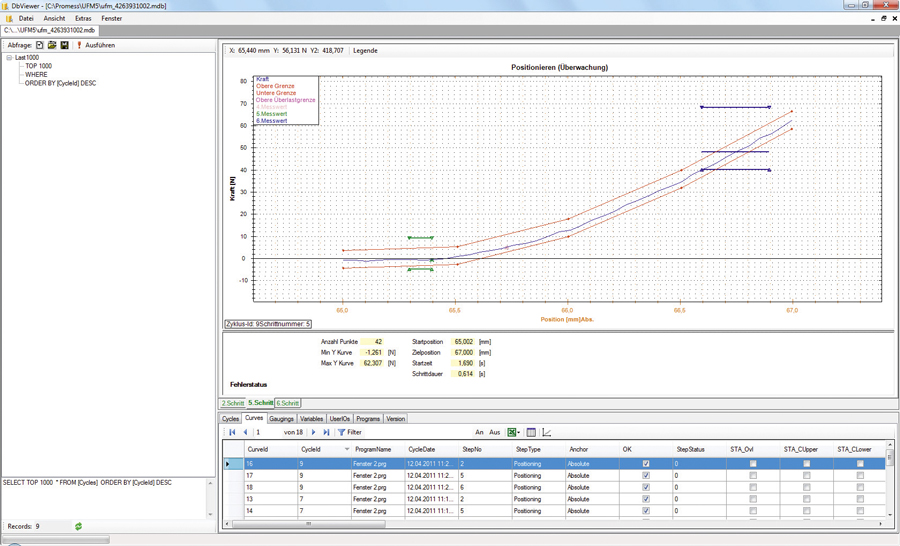

All process data including the curves can be stored in a database which is linked by a plugin. All common database formats such as Oracle, MS SQL and Access are supported. A separate database is created for each station. The database can be analyzed using the DB Viewer with its extensive querying and filtering options. Programs can be stored and re-used at any time. Since the program changes can be traced, this provides 100% traceability throughout the entire production. The data can also be exported in Excel format at any time.

The UFMR Barcode plugin can be used to change the program within the UFM software using a barcode scanner. While the program runs, the barcode scanner can be used, for instance, to transfer a part ID using the UFM dialog function. Optional we offer barcode scanners, configured and equipped with driver.

Keep calibration simple: the UFMR Calibrate plugin was developed for calibrating the force transducers of our assembly presses. The integrated range calibration of the PROMESS PDFM-S digital preamplifier supports 2-point calibration as well as characteristic diagram calibration. Calibration can be performed most simply using the PROMESS calibration set that contains a reference force transducer and the KT-V5 evaluation unit with display.

The UFMR QDE plugin allows quality assurance data to be exported to the QS-STAT statistics software from Q-DAS and supports process monitoring and opimization. Measurement, auiliary and description data can be exported from each joining program as characteristic data.

The UFMR IPM plugin makes it possible to export process and measurement data to the IPM process data management from CSP and thus supports process monitoring and opimization.

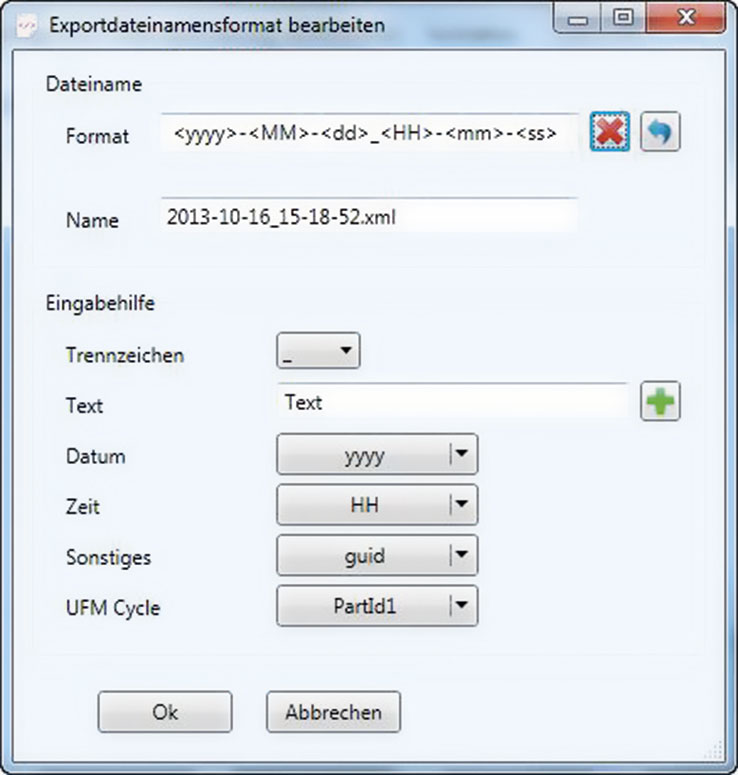

PROMESS has developed the plugin XML-Writer for the export of process data like measurement data, curve data or variable values. Subsequently, the XML data can optionally be processed and analyzed.