The UFM CLASSIC series NC joining systems offer a wide range of load capacities and stroke options, making them highly customizable for any task. Equipped with strain gauges or piezo force measurement, it delivers precision with 0.01 mm positioning accuracy via a synchronous belt and ball/roller gear drive. The flexible drive system, with either an angled or inline motor, ensures easy integration into assembly lines or manual workstations. Controlled by PROMESS software, it guarantees reliable, real-time force monitoring and data storage, while the 24-bit signal resolution and user-friendly interface provide maximum accuracy and traceability, supporting SQL Server and Oracle for seamless data management.

| UFM | Force [kN] | Stroke [mm] | Speed [mm/s] | Article-No. |

|---|---|---|---|---|

| 500 | 400 | 50 | 37510500G2 | |

| 300 | 450 | 100 | 3740300G2 | |

| 150 | 400 | 145 | 3740151G2 | |

| 100 | 180 | 110 | 374111G2 | |

| 100 | 330 | 200 | 374103G2 | |

| 80 | 330 | 200 | 374091G2 | |

| 80 | 180 | 150 | 374181G2 | |

| 60 | 330 | 240 | 374065G2 | |

| 60 | 180 | 150 | 374060G2 | |

| 40 | 330 | 240 | 374043G2 | |

| 40 | 180 | 150 | 374040G2 | |

| 30 | 350 | 230 | 374130G2 | |

| 30 | 180 | 150 | 374131G2 | |

| 20 | 350 | 230 | 374023G2 | |

| 20 | 180 | 150 | 374125G2 | |

| 15 | 200 | 240 | 374014G2 | |

| 12 | 200 | 240 | 374012G2 | |

| 5 | 200 | 240 | 374005G2 | |

| 3 | 100 | 120 | 374003G2 |

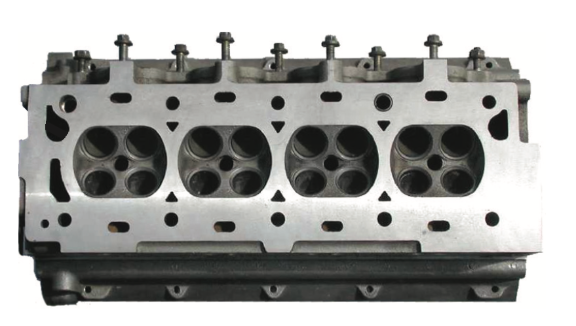

Valve seat and valve guide assembly process.

The lack of depth verification led to multiple assembly issues, affecting the quality and reliability of the final product.

PROMESS used its motion controller to measure the valve seat pocket depth and gauge the seat height, ensuring accurate verification of the final seat depth.