The UFM Line5 RX Universal Joining Modules provide a flexible and powerful solution for a wide range of assembly, joining, inspection, and testing applications, handling forces from 0.2 to 500 kN. With multi-axis capabilities, it can manage complex tasks like synchronization and forming with just one controller. The sturdy spindle drive ensures precise force control in both push and pull directions, supported by built-in force sensors and encoders for accuracy. Available in inline or parallel designs, it is built to last, offering up to 15 million strokes. Easy to set up, the RX software allows for simple control and monitoring through any web browser.

| Inline | Force [kN] | Stroke [mm] | Speed [mm/s] | Article-No. |

|---|---|---|---|---|

| 200 | 350 | 100 | RLWIK200D-035-010 | |

| 100 | 350 | 200 | RLWIK100D-035-020 | |

| 60 | 350 | 250 | RLWIK060D-035-025 | |

| 30 | 750 | 250 | RLWIK030D-075-025 | |

| 30 | 350 | 250 | RLWIK030D-035-025 | |

| 10 | 200 | 300 | RLWIK010D-020-030 | |

| 3 | 200 | 200 | RLWIK003D-020-020 | |

| 1 | 200 | 200 | RLWIK001D-020-020 |

| Parallel | Force [kN] | Stroke [mm] | Speed [mm/s] | Article-No. |

|---|---|---|---|---|

| 200 | 350 | 100 | RLWPK200D-035-010 | |

| 100 | 750 | 200 | RLWPK100D-075-020 | |

| 100 | 350 | 200 | RLWPK100D-035-020 | |

| 60 | 350 | 250 | RLWPK060D-035-025 | |

| 30 | 350 | 250 | RLWPK030D-035-025 | |

| 10 | 200 | 300 | RLWPK010D-020-030 |

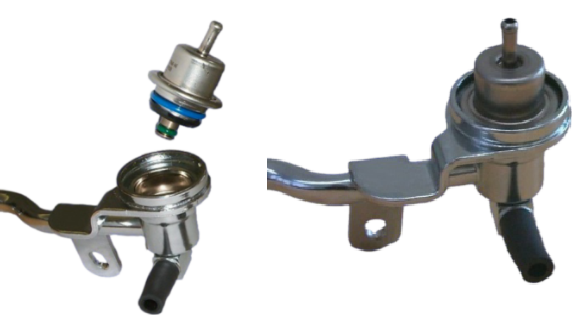

Automotive OEM and tier two suppliers experienced intermittent fuel rail leaks, despite all parts passing standard leak tests.

Leaks occurred in about one in 100,000 rails, undetected by conventional pressure testing, posing a safety risk.

200-part tests were conducted using PROMESS equipment which detected 100% of failed components missed by the standard tests.