The UDM 5 is the latest in universal torque systems, offering unmatched precision with its advanced measuring technology and 0.5% accuracy. With seven sizes covering a range from 1.5 to 200 Nm, it’s ideal for various applications. Its robust design ensures long-term use, while integrated drive and torque measurement minimize downtime and maintenance costs. Easy-to-use technology reduces training time, and low noise levels make it ideal for clean environments. The modular control system, combined with PROMESS software, offers seamless operation and real-time monitoring, ensuring optimal performance and reliability for your assembly processes.

| Module | Load Range [Nm] | Revolution [U/min] | |||||||

|---|---|---|---|---|---|---|---|---|---|

| UDM5 | 100 | 300 | |||||||

| UDM5 | 60 | 300 | |||||||

| UDM5 | 30 | 600 | |||||||

| UDM5 | 10 | 600 | |||||||

| UDM5 | 5 | 600 | |||||||

| UDM5 | 1,5 | 600 | |||||||

| UDM5 | 200 | 80 |

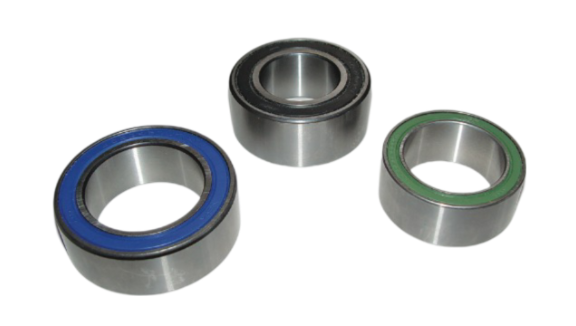

In precision bearing manufacturing, every bearing undergoes a quality test to measure breakaway and running torque, determining the bearing preload before shipment.

The existing system lacked repeatability and stability in measuring torque, leading to inconsistent quality checks.

PROMESS Solution, with integrated torque monitoring and motion control provided stable and repeatable measurements for both breakaway and running torque.