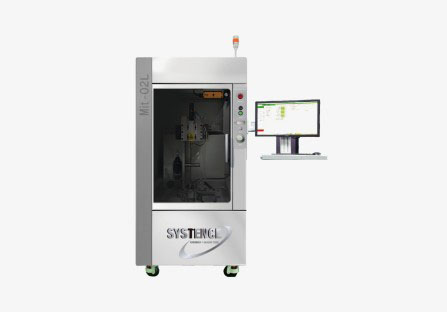

We helped ensure the safety and reliability of automatic insulin pen injectors by providing custom test stations for major medical device manufacturers. Accuracy is tested on our advanced workstations. By checking the injection force, torque, and precision of injected quantity through simulating real-world situations, we have helped customers to increase quality assurance accuracy and modernize efficiency. This has improved the production process. Reduce manual testing and ensure compliance with regulatory standards. Our testing solutions help customers achieve the highest quality of joint and QA for the insulin pen test execution. This ensures the best results in terms of quality and resource management.

We provided an advanced test station to one of the biggest pharmaceutical companies, improving quality assurance and usage safety of autoinjectors. Tests from precise injection force to needle performance and dosage accuracy had been conducted on our custom-built workstation to ensure every stage performs perfectly. Automation of the test cycle minimized manual testing and maximized productivity. Our solution ensures that strict regulatory standards are met and production accuracy meets the highest level. Confidence in delivering reliable, high-quality auto-injectors to market for customers increased even more after our solution installation.