-

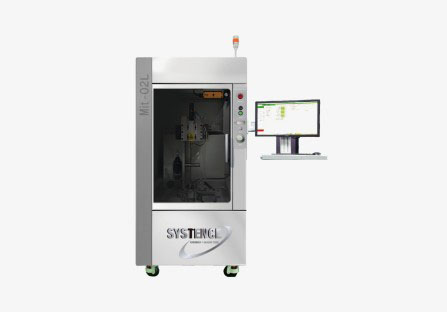

Automatic test of cup drawing force

-

Injection Force

-

Needle cover lockout force

-

Extended Needle Length

-

Drug dosage monitoring

-

Measure the time required for the complete discharge of liquid from the start to the completion of injection

-

Display, record, and determine the volume of the prompt sound when measuring the start/end of injection